In sectors such as petrochemicals, logistics, and energy, an undetected spark can trigger losses in the millions. Fire detection systems not only protect operational continuity but also save lives in critical seconds. Early detection makes the difference between a controlled intervention and an industrial catastrophe.

Why are fire detection systems critical?

The inherent risks in ATEX zones and industrial processes are numerous. Volatile chemicals, extreme temperatures, and complex electrical systems create scenarios of constant risk. An undetected fire compromises infrastructure valued in the millions and, most seriously, puts the lives of personnel at risk.

Legal penalties for regulatory non-compliance are severe. Adherence to UNE, EN, and ATEX standards is not optional: it is mandatory. Spanish regulations, especially Royal Decree 244/2019, establish strict requirements for critical industrial facilities. Furthermore, insurance companies require these systems as a condition for civil liability coverage.

Risk perception in industrial companies increasingly emphasizes prevention. Investing in early detection is more economical than managing a post-fire crisis. The costs of operational downtime, structural damage, and potential litigation far exceed the installation budget.

Types of Industrial Fire Detection Systems

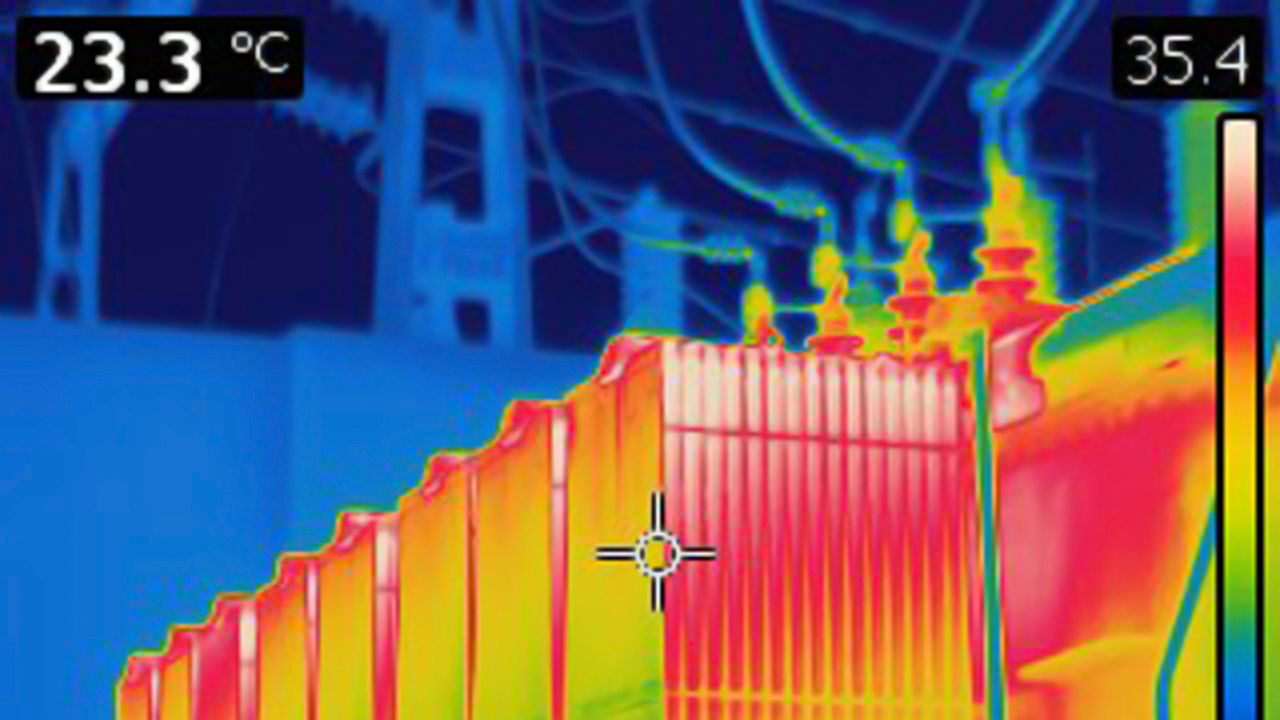

Thermal Detection with Thermographic Cameras

Thermal imaging cameras detect temperature changes before flames become visible. This technology is especially valuable in ATEX zones, where traditional smoke detectors are ineffective. They measure infrared radiation and generate alerts when temperatures exceed predefined thresholds.

The advantages are significant: early detection of hotspots without direct contact with the heat source. In chemical plants and refineries, these cameras offer wide coverage of large areas with precise thermal resolution. They are particularly effective in spaces with forced ventilation, industrial dust, or vapors where conventional detectors fail.

Aspirating Smoke Detectors

These systems continuously draw air from pipes distributed throughout the facility. They detect smoke particles at minimal concentrations, before a fire becomes evident. Ultra-precise sensitivity is ideal for dusty environments.

These detectors operate in two stages: early warning and alarm. They allow for intervention before flames develop. In logistics plants, chemical warehouses, and data centers, this system is preferred for its predictive capabilities.

Flame Detectors

Flame detectors identify ultraviolet and infrared radiation emitted by fire. They are effective in open areas, environments with flammable gases, and spaces where other types of detection are insufficient. Their response speed is superior: they react in milliseconds upon contact with a flame.

The main limitation is that they do not detect smoke without a flame. Therefore, they are frequently integrated with other systems for comprehensive coverage.

Integrated Multi-Technology Detection

Modern security installations combine technologies: thermal sensors, smoke detectors, and flame detectors in a single unit. This redundant approach ensures that no scenario goes undetected. A fire that one type of detector misses will be detected by another.

Integration also simplifies maintenance and reduces false alarms. Intelligent algorithms analyze patterns from multiple sensors before triggering an alert.

Integration with Alarm Receiving Centres (ARCs) and SCADA Systems

Modern detection systems integrate with Alarm Receiving Centres (ARCs). The ARC receives alerts instantly, verifies the information, and deploys emergency resources. The Microsegur Turkana system exemplifies this integration: it combines automatic detection, human verification, and coordinated response.

SCADA integration enables remote monitoring of detector status, predictive maintenance, and trend analysis. Large industrial plants require this real-time visibility to proactively manage risk.

Advantages of Choosing a Specialized Integrator

Selecting an expert integrator like Microsegur guarantees several advantages: a preliminary technical audit that identifies site-specific risks, customized design without generic solutions, planned preventive and corrective maintenance, and regulatory compliance certification.

CRA Turkana’s service provides 24/7 alert response, intelligent incident verification, and immediate coordination with emergency services. Equipment certified for demanding environments ensures reliable operation when it’s critical.

Predictive maintenance through SCADA integration reduces downtime. Technicians detect anomalies before failures occur, replacing components within scheduled windows instead of managing unexpected crises.

Prevention Before Crisis

The maxim of industrial safety is unequivocal: a well-designed fire detection system protects investments, preserves operational continuity, and, most importantly, saves lives.

Every industrial facility has unique characteristics. Refineries, chemical plants, and logistics centers require specific approaches. The initial professional assessment is an investment in operational peace of mind.

If you manage complex industrial facilities or critical infrastructure, it’s time to review your current detection system. Microsegur offers free technical audits to assess your regulatory compliance and recommend optimizations. Looking to protect your industrial facility against fire? Contact us for a no-obligation assessment.