Armored cables are a fundamental solution for installing advanced perimeter security systems, especially in industrial environments where conditions are extremely demanding. Their reinforced design guarantees operational continuity even in the face of mechanical, climatic, or biological stresses that would compromise conventional cables.

What are armored cables and why are they essential?

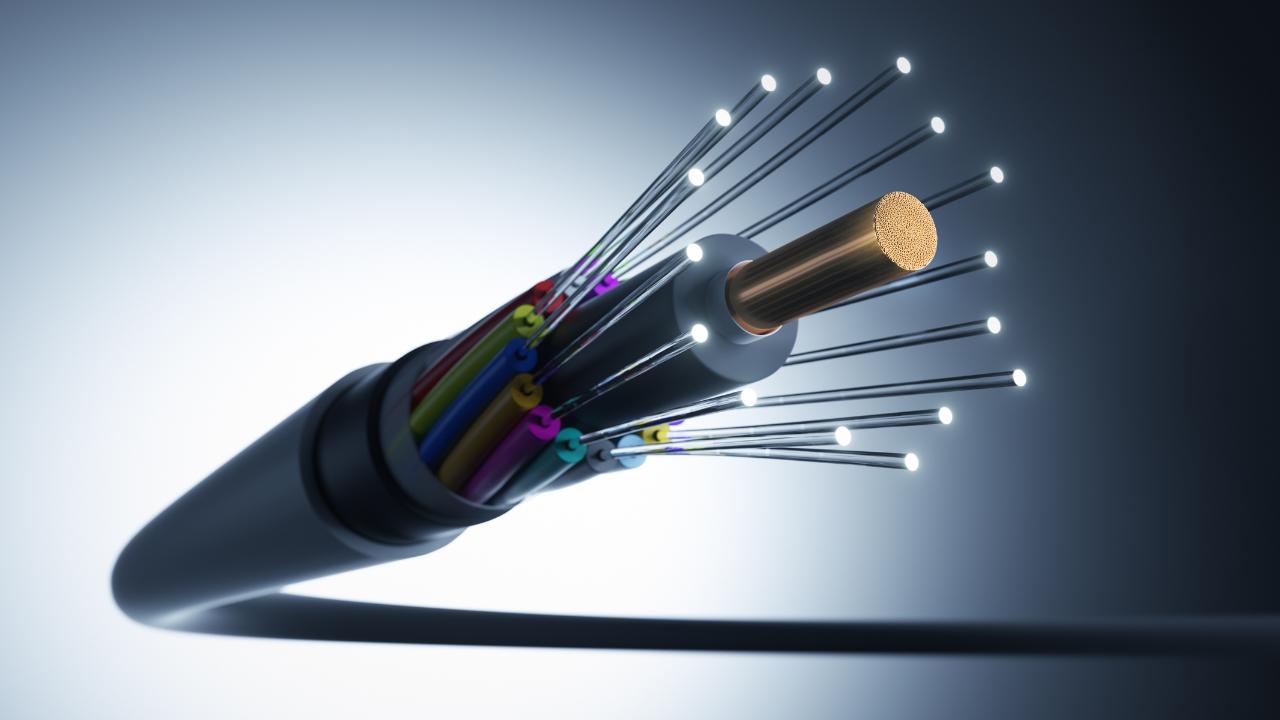

An armored cable incorporates an additional layer of metallic protection—generally steel or aluminum—that surrounds the electrical conductors. This armor gives the cable exceptional resistance to impacts, compression, tension, and rodent damage. It also provides electromagnetic shielding that reduces interference in the transmission of critical signals.

The metallic armor effectively protects the electrical conductors from external damage, allowing their use in buried installations and harsh environments. In CCTV video surveillance, access control, and perimeter detection systems, where the integrity of the cabling determines the reliability of the entire system, this additional protection is indispensable.

The most commonly used armor materials include galvanized steel wires, steel strips, corrugated strips, and metal braids. The selection of the specific type depends on the required level of protection, environmental conditions, and the expected mechanical stresses during the installation’s service life.

Types of armored cables according to their construction

Armored cable with steel wires

Galvanized steel wire armor is mandatory in locations with a risk of fire or explosion, as indicated by ATEX zone regulations. This type offers very good mechanical protection, excellent rodent resistance, and adequate performance under tensile stress. In technical nomenclature, it is identified with the letter “M” or “MA” when aluminum is used in single-core cables.

Armored cable with steel strips

Constructed with two helically arranged strips, it provides superior protection against impacts and mechanical compression. Its standard designation uses the letter “F” or “FA” depending on the material used. It is particularly suitable for critical industrial installations where the risk of crushing is high.

Corrugated Strip Armor Cable

Manufactured with corrugated tinned steel or aluminum strip, it combines mechanical protection with greater installation flexibility. It is identified by the letters “F3” or “FA3”. Its design allows for smaller bend radii, facilitating installation in confined spaces without compromising structural integrity.

Braided Wire Armor Cable

The steel wire mesh armor (designated “SY”) requires a minimum coverage of 80% to be effective. It is the lightest and most flexible option, allowing for mobile services and smaller bend radii. Ideal when mechanical protection is needed without sacrificing cable handling during installation.

Applications of Armored Cables in Enterprise Security Systems

Installations in ATEX Zones

The Construction Products Regulation (CPR) mandates the installation of high-security cables in ATEX zones, requiring a minimum fire reaction class of Cca-s1b,d1,a1. The petrochemical industry, refineries, gas plants, and flammable product storage facilities require specific armored cables that meet extremely stringent regulations.

In these environments, armored cables not only provide mechanical protection, but their flame-resistant properties and low emission of corrosive fumes are critical for overall safety. Microsegur implements cabling solutions adapted to ATEX equipment in its most technically complex projects.

Perimeter Security in Critical Infrastructure

Perimeter surveillance systems in solar plants, wind farms, power plants, and ports require extensive cable runs in harsh environmental conditions. Armored cables withstand continuous exposure to UV radiation, extreme temperature variations, humidity, and potential damage from heavy machinery during maintenance operations.

Steel-armored cables offer a resistance of up to 1,500 PSI, which is very important in certain industrial environments. This ability to withstand high loads without degradation allows for direct burial installations, reducing ductwork costs and system vulnerabilities.

CCTV Surveillance Cabling

In security camera systems, especially those integrating IP technology with PoE (Power over Ethernet), the choice of cable determines both image quality and power stability. Armored Cat6 or Cat6A cables with UV protection are ideal for outdoor installations, guaranteeing data transmission at 10 Gbps without degradation from electromagnetic interference.

The grounded metal armor provides additional shielding, reducing electrical noise that could compromise high-definition video signals. This is especially relevant in industrial environments with abundant electrical machinery that generates electromagnetic fields.

Technical and Operational Advantages of Armored Cables

Durability and Extended Service Life

The multi-layer protection of armored cables significantly extends their service life, reducing corrective maintenance costs and minimizing security service interruptions. Their resistance to chemicals, oils, and hydrocarbons makes them ideal for petrochemical environments where conventional cables would fail prematurely.

Installation in Extreme Conditions

They can be laid directly underground without the need for additional protective conduit, simplifying the execution of complex projects. Their performance in the event of accidental excavation or impacts from tools makes them the safest option for long-term infrastructure.

Compatibility with Integrated Systems

Modern armored cables are fully compatible with integrated security management systems, enabling the convergence of video surveillance, access control, intrusion detection, and communications within a single, robust, and reliable network infrastructure.

The professional selection and installation of armored cables is a key differentiator between merely functional security systems and those that are truly reliable in the long term. In complex industrial and commercial environments, where operational continuity is paramount, this investment in quality infrastructure translates into operational peace of mind and effective protection of critical assets.

Do you need expert advice for your security project? Our technical team is ready to assess your specific needs and design the optimal cabling solution. Contact Microsegur and discover how we can strengthen your security system’s infrastructure.