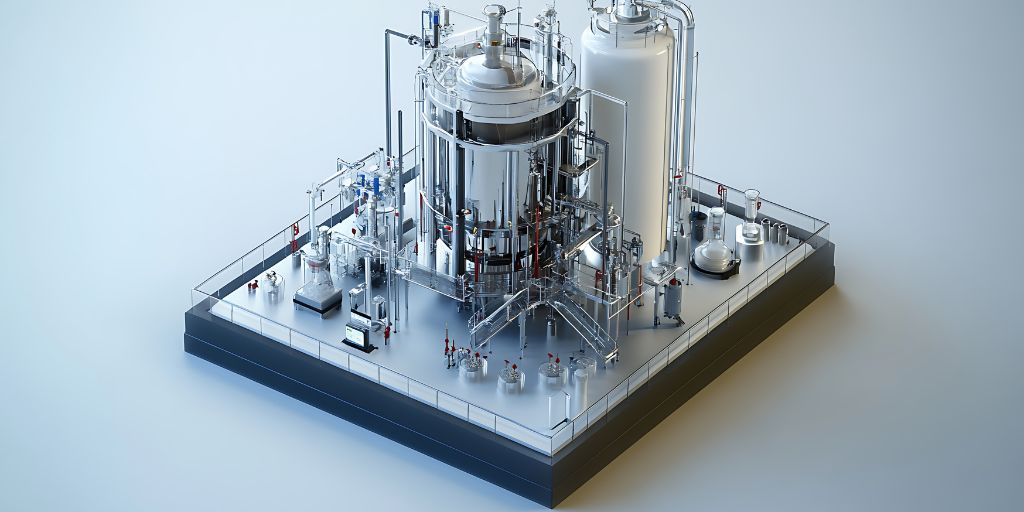

Modern industry faces unprecedented challenges. Automation advances by leaps and bounds, regulations become more demanding, and competition pressures for maximum operational efficiency. In this context, conventional surveillance is no longer sufficient. Companies need more than recording what happens; they require real-time supervision of their most critical processes. Microsegur’s industrial process supervision systems go beyond traditional video surveillance. They integrate intelligent analysis, anomaly detection, and centralized control to ensure that every industrial variable operates within safe parameters. From temperature and pressure to personnel access and machinery operation, our systems monitor, analyze, and alert when necessary.

What are industrial process supervision systems?

Industrial process supervision systems are technological solutions that monitor critical variables of an industrial operation in real time. Unlike traditional surveillance, which is limited to capturing images, these systems integrate multiple data sources—IP cameras, sensors, SCADA systems, PLCs, and automation—into a centralized platform.

An effective supervision system detects deviations before they become problems. If a temperature rises above the safe threshold, if there’s a pipe leak, if unauthorized personnel access a restricted area, or if a production line stops unexpectedly, the system identifies it instantly. This predictive prevention capability is the difference between smooth operation and costly downtime.

Supervision solutions offered by Microsegur

Industrial IP Video with intelligent analysis

Video surveillance is no longer just about recording. Our industrial IP cameras incorporate intelligent analysis that automatically detects visual anomalies. The system identifies process changes, identifies unauthorized intrusions in critical areas, and can generate alerts before the operator notices the problem.

We integrate these cameras with sensors and automation systems, allowing video analysis to trigger automatic responses or supervised alerts for immediate verification.

SCADA and remote data acquisition systems

In complex plants, SCADA system integration is essential. Microsegur specializes in centralizing technical and industrial signals within a unified security platform. This means that operators and security managers access a single panel where they visualize both machinery status and physical security events.

The operational advantage is immediate: reduced response times, better coordination between security and operations teams, and automatic documentation of all events for regulatory compliance.

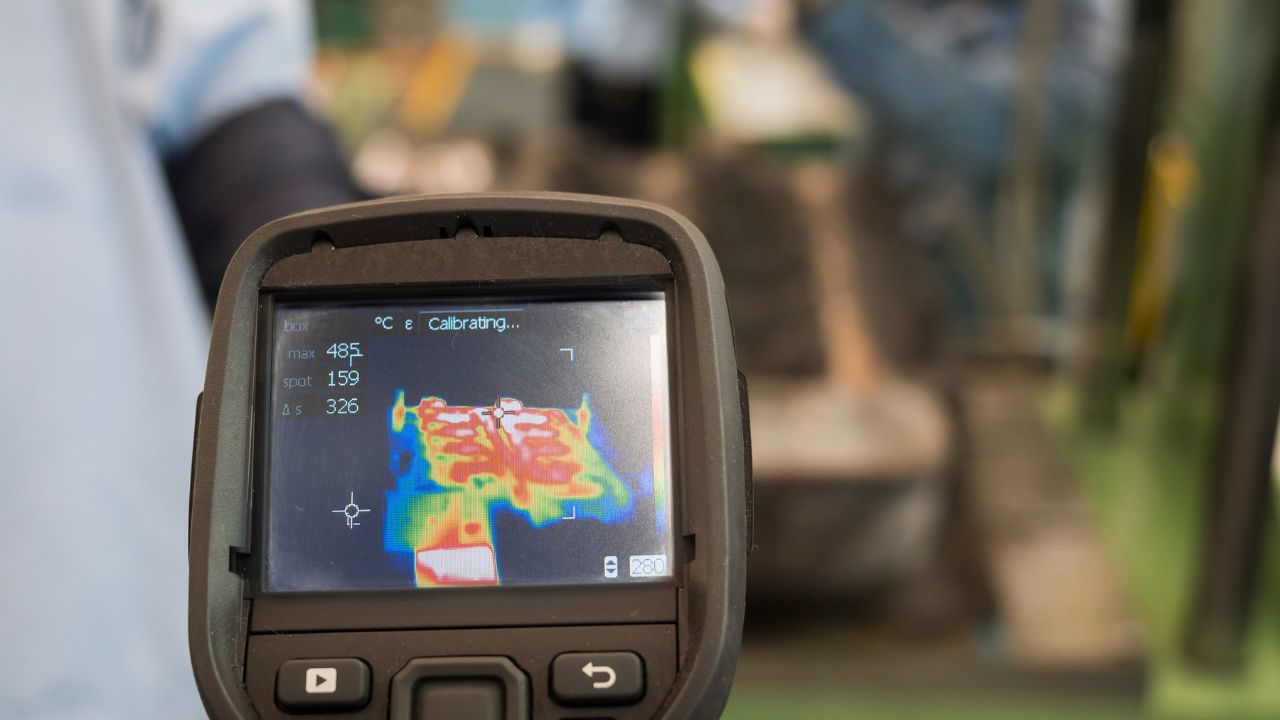

Thermal cameras for process control

Thermal cameras are crucial allies in industries where temperature control is vital. Microsegur installs solutions that detect heat anomalies in critical equipment, preventing fires, overheating shutdowns, and gas leaks. In refineries, chemical plants, and processing centers, these cameras operate 24/7, identifying hot spots that could indicate imminent failures.

Integration with ATEX systems

In explosion risk zones, safety admits no compromises. Microsegur designs and installs ATEX-certified equipment that operates without ignition risk. We have proven experience in refineries, gas plants, chemical facilities, and energy infrastructures where ATEX standards are legally mandatory.

CRA Platform – Turkana

Our Alarm Receiving Center platform integrates intelligent verification of technical events. It’s not just about receiving alerts; our system automatically categorizes the type of anomaly, its severity, and the necessary response protocol.

This significantly improves predictive maintenance, allowing scheduled interventions before costly failures, and directly reducing operational expenses.

Benefits of advanced industrial supervision

- Reduction of risks and unscheduled downtime. Early detection of anomalies prevents minor problems from becoming critical incidents. Operations run without unexpected interruptions.

- Energy and operational efficiency. With complete real-time visibility, teams optimize energy consumption and adjust processes for maximum productivity.

- Greater control over critical environments. Even if the installation occupies dozens of hectares or is distributed across multiple locations, managers see everything from a single platform.

- Regulatory compliance. Especially in regulated sectors such as energy, chemicals, and food, these systems generate automatic records that demonstrate compliance with Real Decreto 244/2019 and other applicable regulations.

- Remote visibility. Executives and security technicians access real-time information from any location, improving decision-making.

- Alert and response automation. The system not only alerts; it can execute automated responses or escalate alerts according to predefined protocol.

How does Microsegur help with industrial supervision?

We begin with a detailed technical diagnosis of your operation, identifying critical points and vulnerabilities. Then we design a solution tailored to your specific needs.

Projects are implemented turnkey: architecture design, equipment installation, integration of existing systems, and personnel training. We have cutting-edge technology validated in extreme environments—from refineries to nuclear plants—and offer scalable systems that grow with your operation.

Do you need to transform the security and operational efficiency of your industrial facility? Discover how Microsegur has helped companies in critical sectors improve control, reduce risks, and comply with regulations. Contact our team for a free consultation and learn about a proposal tailored to your operation.